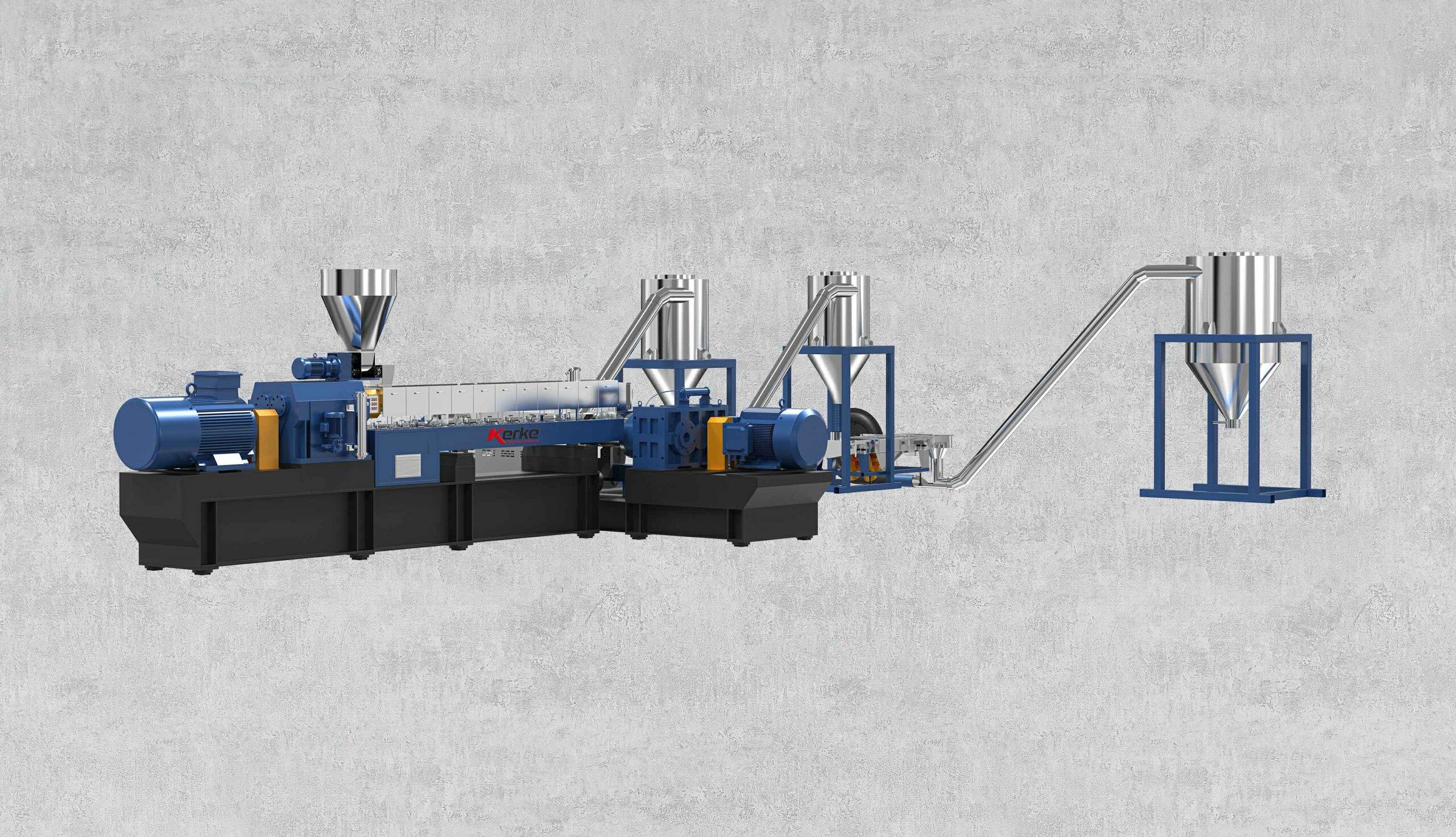

The first stage consists of a KTE-series high-speed co-rotating twin-screw compounder , and the second stage employs an SE-series low-speed single-screw extruder , arranged in a vertically orthogonal configuration to form a dual-stage composite compounding extrusion system .

This design synergistically combines the strengths of co-rotating twin-screw and single-screw technologies:

- The twin-screw provides positive conveying , efficient plastification/compounding , and shear dispersion with no head pressure backflow , preventing overheating from excessive shear .

- The single-screw delivers high-pressure extrusion with low-speed, low-shear operation , avoiding thermal degradation risks .

By decoupling process functions between stages, the system increases independent operational variables for distributed optimization of each process phase , achieving superior productivity and efficiency .

- It is widely adopted for:Heat-sensitive material systems (e.g., PVC, XLPE) Large-scale devolatilization,such as Halogen-free flame-retardant cable compounds,Electromagnetic shielding materials,High-load carbon black masterbatches and Post-treatment of dehydrated rubber.

Typical Applications:

- EVA pelletization with foaming agents or crosslinking additives

- Wood-plastic composite (WPC) pelletization

- High-concentration carbon black masterbatches

- XLPE pelletization for cables or PEX pipes