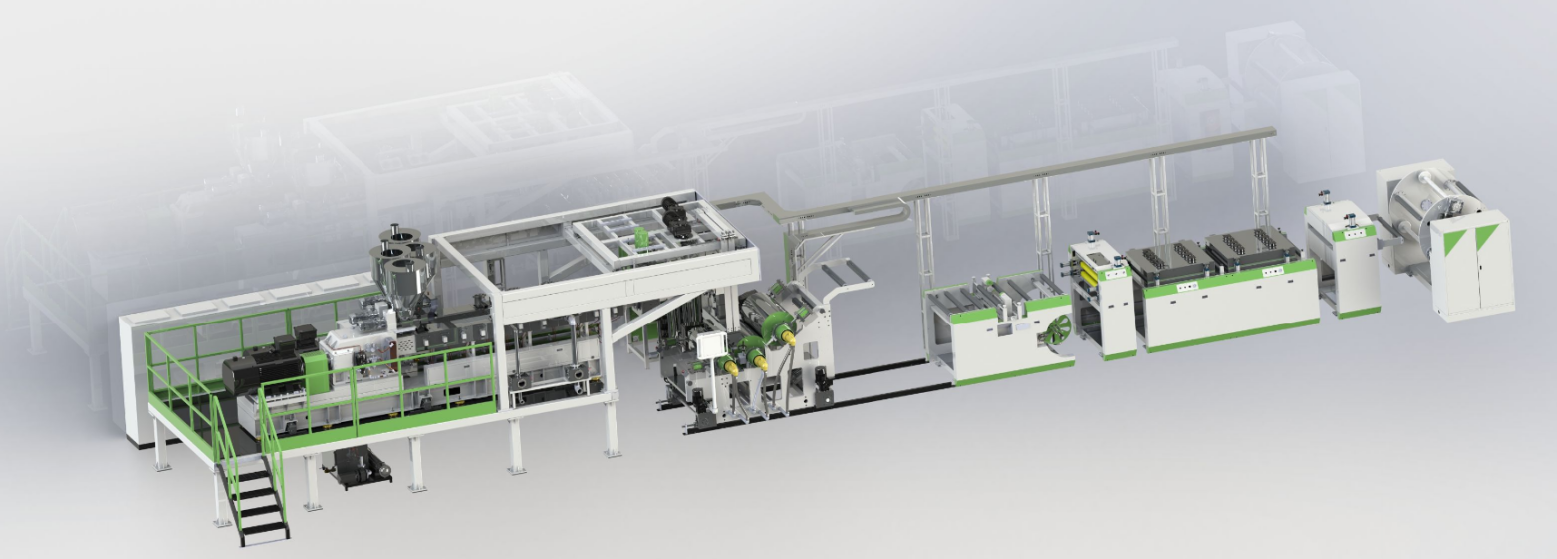

PET/PLA Extrusion Sheet Production Line

- Our PET/PLA extrusion sheet production line integrates advanced international technologies and innovative process formulas to develop a crystallization-free drying system . Featuring precision three-roll calendering technology and a patented twin-screw extruder automatic material replenishment device (Patent No.: 2020223016414), this line effectively reduces raw material viscosity and enhances cooling efficiency, significantly improving sheet quality and output. The production line is characterized by:

- Eco-friendly, low energy consumption

- Simplified operation and compact structure

- Uniform plasticization, stable extrusion, and high productivity

HDPE Geomembrane

- HDPE geomembrane, or High-Density Polyethylene Geomembrane , is a waterproof barrier material produced from (medium) high-density polyethylene resin. Key advantages include:

- Outstanding environmental stress crack resistanceLow-temperature resistance, anti-aging, and corrosion resistance

- Wide operating temperature range (-60°C to +60°C)Service life of up to 50 years

- Typical Applications :Landfill liners (municipal solid waste, industrial waste)Sewage treatment facilitiesArtificial lake waterproofingTailings management

LVT Flooring Production Line Innovation

- Traditional steam press composite LVT flooring lines rely on boiler-heated steam for prolonged molding, resulting in high energy consumption, labor-intensive operations, and large footprint . Our newly developed LVT soft composite flooring line addresses these challenges through:

- Breakthrough structural design

- Elimination of steam molding processes

- Compact layout and automated controls

- This innovation fills a domestic market gap while offering superior efficiency and simplified workflow compared to conventional systems.

Typical Applications

- PET adhesive films

- TPO waterproof membranes

- PVB/EVA adhesive films

- WPC/LVT wood-plastic sheets