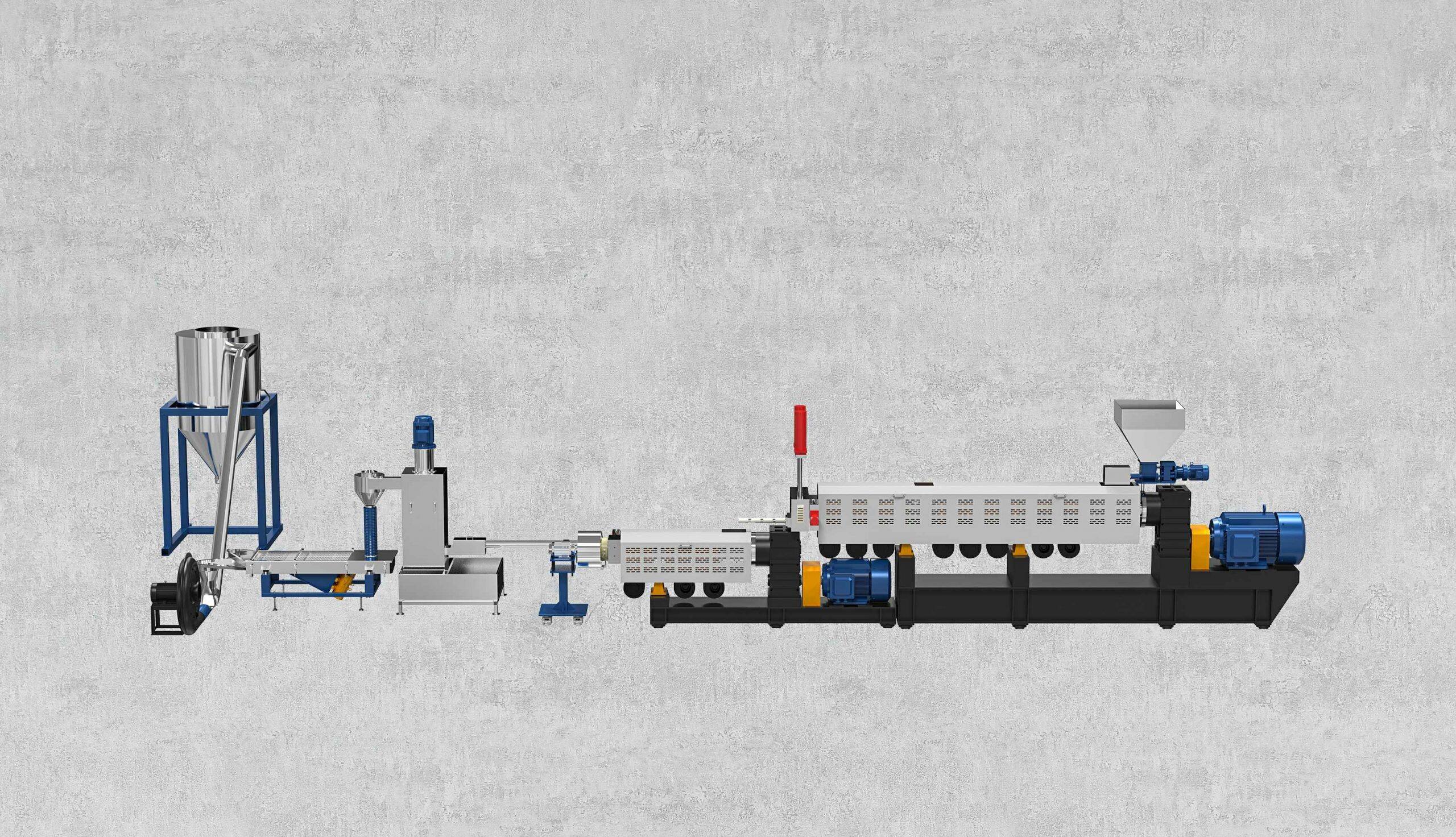

The SE/KTE Series two-stage extruder system is primarily designed for waste plastics recycling/filling applications and one-step modification processes for post-consumer plastics.

Technical Specifications:

- Upper Single-Screw Extruder

- Executes melting of waste plastics

- Features enlarged feed port design to enhance production capacity

- Incorporates optimized screen-changing mechanism for improved filtration efficiency

2.Lower Twin-Screw Extruder

- Enables addition of fillers (e.g., calcium carbonate), glass fibers, and functional additives

- Provides superior mixing, dispersion, modification, and reinforcement effects

- Ensures enhanced product quality while reducing energy consumption

Key Advantages:

- Integrated system for closed-loop plastics recovery

- Energy-efficient processing of mixed plastics and industrial plastic waste

- Suitable for engineering thermoplastics modification and structural foam applications

Typical Applications:

- Recycling and modification granulation of TPE elastomer scrap films/sheets

- Recycling granulation of PP/PE sheets/boards/scrap films (e.g., polypropylene/polyethylene)

- Recycling granulation of PC/ABS injection molding sprues and runners